Our activity

Detailed exploration stages in the Feyzabad Naein Mining and Processing Complex It is generally done using a 10-step process. These steps in mining include the following:

- Preliminary studies and determination of the deposit type

- Preparing geological and structural maps

- Exploration pattern design

- Facies blocking

- Surface sampling and powder drilling

- Preparing a potential map

- Drilling program design

- Core drilling

- Logging and sampling

- Analyzing results and preparing a reserve map

Mineral extraction

The overall mining and tunneling cycle in the Feyzabad Nain Mining and Processing Complex includes the following:

- Drilling

- Blasting & Charging

- Evacuation of materials from Blasting

It is also worth noting that to complete the three steps described above, many preparations and supports are required, including the following:

- Electricity

- Compressed air

- Ventilation

- Water supply

- Barring down

- Survey

- Pumping

- Maintenance

- Equipment

Mineral processing

Lead and zinc They are generally found together in mineral soils due to their nature and conditions of formation, and of course their ratio in different mine soils is different. Therefore, in the production process using mineral soil, both lead and zinc concentrates are produced. In general, the production process in the concentrate factory Feyzabad Naein Mining and Processing Complex It is carried out in three stages: crushing unit, heavy media unit and flotation. The production of lead concentrate, zinc concentrate and zinc tailings (crushed zinc) from the soil of the Feyzabad lead and zinc mine is carried out through the following stages:

- Stone crushing and grinding

- Heavy Media

- Grinding

- Slurry making

- Adding flotation materials

- Flotation operation

- Separation of lead-containing compounds (lead concentrate)

- Separation of zinc-containing compounds (zinc tiling or zinc concentrate)

- Dehydration of products and waste (dehydration and water purification circuit)

- Drying of products and waste

Technical office (exploration and extraction designs and production planning)

The following measures are being taken in the technical office of the Faizabad Nain Mining and Processing Complex to advance mining operations:

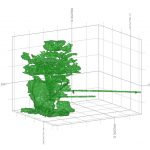

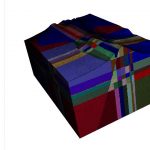

- It receives the detailed exploration data from the exploration unit and enters it into relevant software such as Datamine and designs the extraction method.

- After designing the extraction method, Reference Point < is delivered to the extraction unit on a daily basis so that the extraction operation can be carried out accordingly.

- It receives daily mapping data from the extraction Department, calculates progress, and notifies the extraction department.

- The technical office, in cooperation with the extraction unit, is also responsible for the tunnels’ stability check, which is done with Rhino و Flac 3D softwares.

Software used in projects in the Technical Office Department:

- Geology and Exploration: Arc GIS, Rock Works, Envi, Dtamine RM, Map info Discover, Datamine EM Core profiler

- Extraction and exploitation: Autocad, Civil3D, Datamine OP, NPV Scheduler, Datamine Ug 5Dplanner

- Ventilation and drainage: Ventsim, Pumpsim

- Stability Analysis and Rock Mechanics: Collection of Rocscience, Flac , Udec, 3dec, Rhino, Griddl

Laboratory and quality control

Steps for flotation of samples:

- Sampling from the depot and sample mill with the Radmill device

- Adding chemicals for flotation, including hydrosulfur, PEX, and foaming agents.

- Collecting foam from a flotation sample

- Filter pressing of concentrate and tailings

- Measuring the carat of flotation samples

Working steps of measuring the carat of samples:

- Stone crushing

- Sample refilling

- Sample grinding

- Sample weighting

- Leaching

- Sample analysis with atomic absorption spectrometer

- Calculating and reporting the carat